| Model: | 020 |

|---|---|

| Brand: | UTrust Mould |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

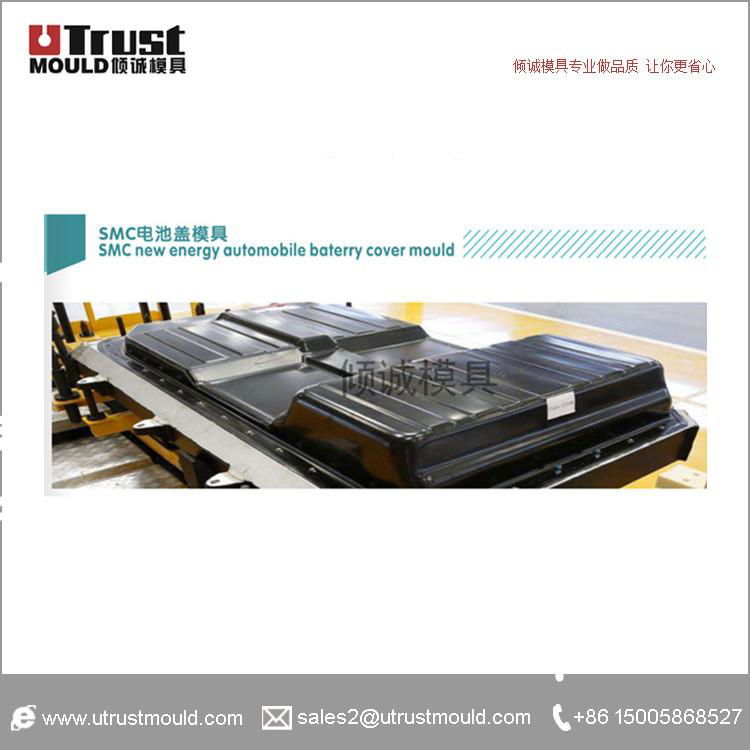

| Label: | SMC battery cover , auto mould , SMC mould |

| Price: |

US $6000

/ set

|

| Min. Order: | 1 set |

Product Description

Mold specifications

|

Name of mould |

SMC battery cover mould for new energy automobile |

|

Steel Material |

P20, 718H, 718HH, 2.738, 1.2343, 1.2344, H13, S136, SKD61, etc |

|

Mould base |

LKM Standard, HASCO Standard Self-made, etc |

|

Hardness |

28-55HRC |

|

Heating system |

electrical heating, oil and temperature style heat |

|

Standard |

HASCO, DME, MISUMI, JIS, LKM, etc. |

|

Design software |

NX_UG, Pro/E, Catia, Mold flow, AutoCAD |

|

Mould Life |

100,000 -500,000 shots |

|

Hot Runner |

Synventive, Moldmaster, HRS, Incoe, Sino, Yudo, etc. |

|

Gate |

Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

|

Valuable Service |

High polishing, Graining, Texture, etc. |

|

T1 Time |

30--60 work days |

|

Parts Delivery |

DHL or UPS,Air Freight or Sea Freight |

|

Cavity Number |

1 |

|

Shaping Mode |

Compression molding |

Mold Making

Material of steel

cavity and core use imported S136 stainless steel with fine polishing, high hardness to get mold's high precision and good quality.

About gate

pin-valve gate ,pneumatic drive the nozzle pin simultaneous high speed open and close action. which can effectively control the injection hole open and close actions on each cavity. reliable seal function, smooth moving, low thermal expansion rate ,long using life and also saves electric energy.

Our Service

1).Product Concept Design

2).Product Reverse Engineering

3).RP/RT Maker(SLA/FDM/CNC for Prototyping)

4).Product Design Optimization

5).Tooling CAD/CAM/CAE,Shorten lead time,Improve molding efficiency

6).Separate part drawing made and assembly production

7).Product & Part Inspection 8.Short Run Production or Parts

9).Supply trial molding parameters

10).Usage and maintenance guide manual

11).Spare parts and detailed parts list

12).Delivery on the spot, adjust for production

13).Training for the tools on the spot

14).Regular visit and service for the customer

Company Information

With more than 10 years’ professional experience, Taizhou Huangyan Qingcheng Mould Company has been striving for the development and production of (FRP) fiber-reinforce-plastic hot press dies(SMCmould/BMC mould) and plastic injection moulds. Our products cover various fields such as automobiles, electronic and electric industry, manufacturing industry, project industry, architecture and engineering industry, sanitary industry and articles of everyday use.

Qingcheng Mouldis always making customer-oriented optimal mould solutions for producing product.Our attitudeof constantly striving for perfection, exquisite technics of our high-quality people, advanced equipment for producing, machining and checking moulds, and, optimal mould parts suppliers, all these together mold the perfect quality of Qingcheng Mould and thus reduce our customers’ production cost and shorten the production period in the broadest sense.Qingcheng Mould has been committed to developing into a global supplier for top-quality mould!

With strong technical strength,Qingcheng Mouldcan manufacture a variety of moulds based on our customers’ requirements and is also happy to help our customers solve various technical problems. “Quality first, credit uppermost and service foremost” is always our service tenet and motto. We are looking forward to the cooperation with you and even greater and common development.

| Payment Terms: | TT/LC/DP |

|---|---|

Member Information

| Utrust mould company | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15005868527 |

| Contact: | Ester (sales manager) |

| Last Online: | 17 Apr, 2015 |